B

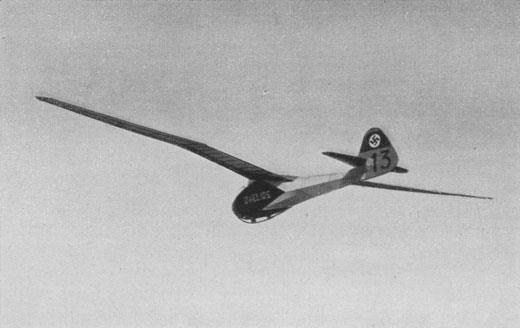

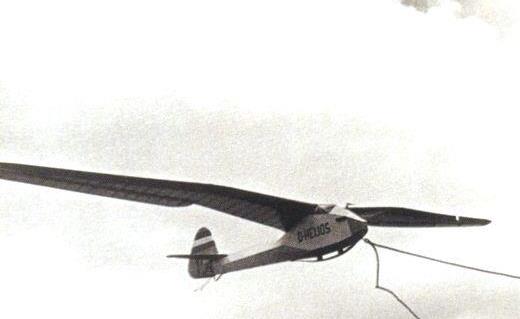

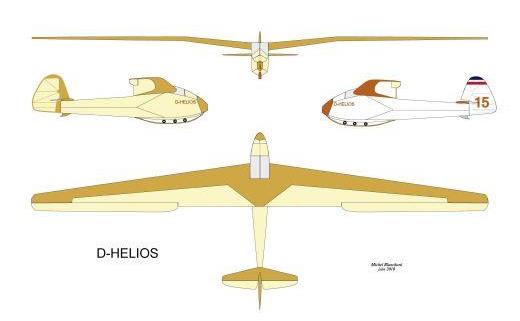

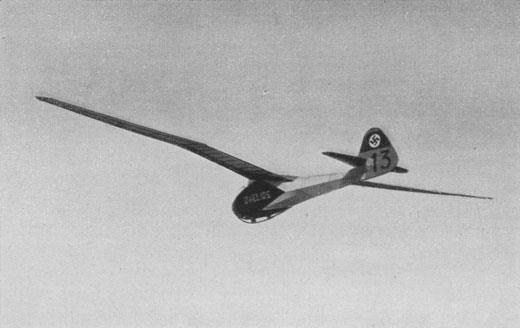

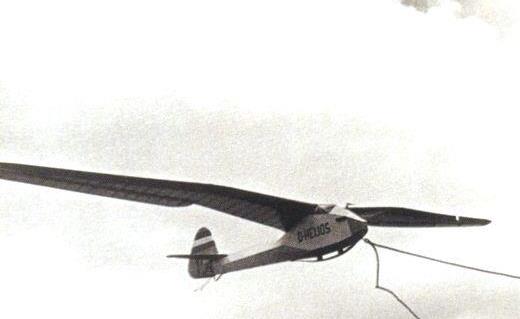

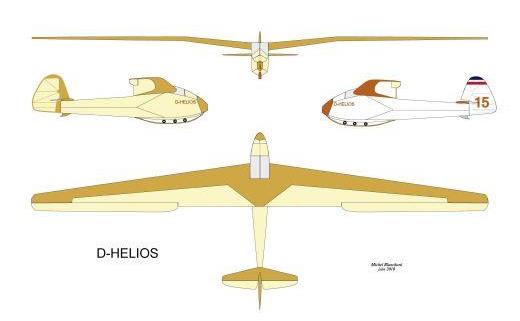

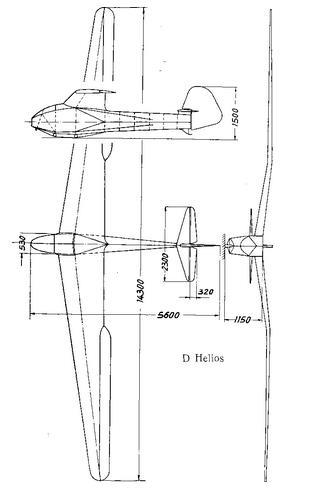

Berlin HFS Helios

| Type |

Single seat glider |

| Dimensions |

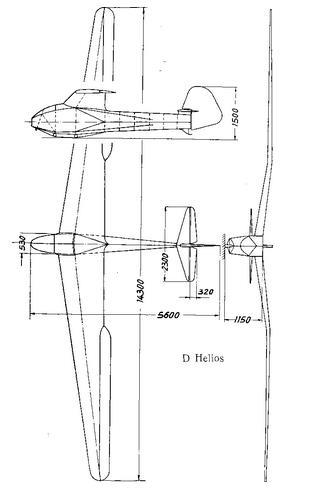

Length 5,6 m, span 14,0 m, wing area 13 m2, aspect ratio 15,1, mean chord 1 m, wing sweep 10º, dihedral 7º, stabilizer 1,1 m2, elevator 0,5 m2, fin total 1,1 m2, rudder 0,9 m2, frontal area 0,41 m2 |

| Weights |

Empty 116 kg flying weight 200 kg wing loading 15,4 kg/m2, |

| Performance |

Flying speed, lowest sinking rate 62 km/h, best gliding ratio 75 km/h |

| Type |

Werk.Nr |

Registration |

History |

|

|

15 |

|

Source: Sailplane and Glider FEBRUARY 1937

This machine was entered at the Rhon both in 1934 and in 1935, and in the latter year carried out a flight of 110 miles, taking 3,5 hours on the journey. This was on an almost calm day (it was the day on which Wolf Hirth soared 261 miles in 7 hours in the first Minimoa), and the time taken is of interest in that the Helios was designed to have a high speed for long distance flying. This was attained by a thin wing section and high wing loading.

The wing section is complicated. At the root it is Göttingen 549, thickened by 18% (this being done to get higher lift values and greater spar depth). One metre out from the root it is Göttingen 549 unthickened; at the bend in the wing it is Gottingen 682, and at the tip M1. The gradual change from one section to the next is linear. As a result of the thin wing section, the wing, which is single-spar and of wood—not metal—can be deflected rather a lot; the amount of deflection at the tips is 27 cm. in an unaccclerated glide.

The bent wing is to give lateral stability. There is also so much longitudinal stability that the wing is almost inherently stable, and only a small horizontal tail surface is needed (fin and elevator 1.1 sq. m.),. This is due to the backward-projecting ailerons, which comprise one-fifth of the whole wing area. There is also an aerodynamic wash-out of incidence of 3 degrees, to give an elliptical lift distribution.

Now for the metal parts of the machine. The ailerons are of dural, with a dural tube for spar and dural sheeting for ribs; the ribs and fittings are fixed to the spar tube by internal rivets in the Junkers manner. The leading edge of the ailerons keeps its shape by being surfaced with dural sheet; as this ensures great torsional stiffness, one central horn suffices for working each aileron. The ailerons are each hinged to the under-side of the wing in five places, and are separated from the wing by a narrow Lachmann slot which opens when the ailerons are pulled down and and are separated from the wing by a narrow Lachmann slot (should we translate this "Handley Page"?), which opens when the ailerons arc pulled down and thus ensures good efficiency in their action. The ailerons can together be pulled 6 degrees downwards to reduce landing speed; they are also arranged to act differentially.

The fuselage is built up of steel tubing; this waschosen on the ground of cheapness and rapidity in construction; in fact, it took two men only 2,5 days to cut and weld the fuselage framework. (The whole machine was built in 6,5 weeks, taking about 2,500 working hours.) The fuselage section is hexagonal in front, eleven-sided in the middle, and diamond- shaped at the tail end. The pilot's head fits into the leading edge of the wing. The wing spar is attached to the fuselage on a very large base --the whole width of the fuselage— by two bolts, a third bolt being in the upper flange of the spar. The torsional loads in the wing are taken in a strong torsion rib.

Flying trials showed that there was something wrong with the air flow at the junction of the wing root with the body, for during landings the air stream would break away and the machine fall out of the pilot's hands when it was still doing 34 m.p.h. The same trouble had been found with the nacelled Fliege, and further trials with both types were needed to remedy it.